Escuber Originals

STEP 6. Calculate Sizes & Decide Configurations.

A trailer’s final configuration and ultimate strength depends on the materials used and their placement in the overall scheme of things. Calculations can be instrumental in selecting the optimum material placement and designing the final configuration.

Trailer calculations, fall into 2 major groups: 1) those used to determine material (and trailer) strength and 2) those which determine a trailer’s dynamic stability while moving down the road. Both help to define the overall configuration. The objective of calculations as discussed in Volume 2, is to arrive at a design which is strong enough and stable enough to handle the required loads with adequate safety margin, while at the same time avoiding excess strength and the associated weight, cost and potential contribution to instability.

While strength calculations are fairly basic, many trials and errors may be required. The components of such a calculation include variables which represent three important aspects – material, shape and load.

- The variable representing the material is called the allowable tensile stress which is a reduced percentage of the material’s tensile strength;

- The variable for the cross sectional shape of the material is either area or a value called moment of inertia;

- The variable for the load configuration is called bending moment and/or shear load. For continuous loads such as dirt or hay, the values are quite different than for loads concentrated in one or two places as you would have with an auto, a horse or a piece of equipment.

By combining two of these variables, it is possible to obtain the third. Thus with items 1 and 3 known, the minimum required moment of inertia can be derived. This is an important capability since load and material stress are often known and material size is in question. Once the safety factor is considered, included and the moment of inertia is calculated, tables can be consulted to select a beam of optimum strength and size to easily support the load in question. Many reference books are available where properties and values for different shaped cross sections are cataloged by material size. The Appendix of Volume 2 includes such a table with an extensive listing of materials commonly used in trailer building. Sometimes knowing the strength of an existing piece of material is necessary. By first obtaining the moment of inertia from tables, using the known adjusted tensile stress, the allowable load can then be computed.

Suppliers can be found for a myriad of materials – steel, bar and rod, steel tube, steel sheet, aluminum, magnesium, fiberglass, etc. But few, if any, can tell you the actual strength of the materials when used as you will use them. Fortunately these suppliers can and are usually happy to provide with the tensile or ultimate stress of the material. However, the actual carrying strength of the product as configured by you is a computed number … one you will have to determine yourself.

Calculations to assess dynamic stability and performance are twofold. One approach uses a formula to obtain the damping ratio at a particular speed. Damping ratio is a number which gives an indication of a traiiler’s ability to return to straight line towing after some disturbance. Damping ratio also predicts the speed at which the trailer, because of its configuration, components and/or loading is apt to become unstable and begin to sway. Reducing a trailer’s tendency to sway is an important consideration since 90% of trailer accidents reported are preceded by trailer sway. And stories from friends and acquaintances abound of the terror (and worse) suffered by those caught in the throes of a whipping trailer.

In addition, the position of a trailer’s center of gravity can aggravate or enhance body roll and stability especially in emergency situations. A trailer that can slide sideways and not overturn gives a driver a much better chance of staying out of serious trouble. Calculations for overturn stability and damping ratio are used to predict this behavior. Volume 3 covers these two subjects which can be most useful in helping you create a trailer that will react mildly, if at all, to disturbances you encounter.

C. PUTTING IT ALL ON PAPER

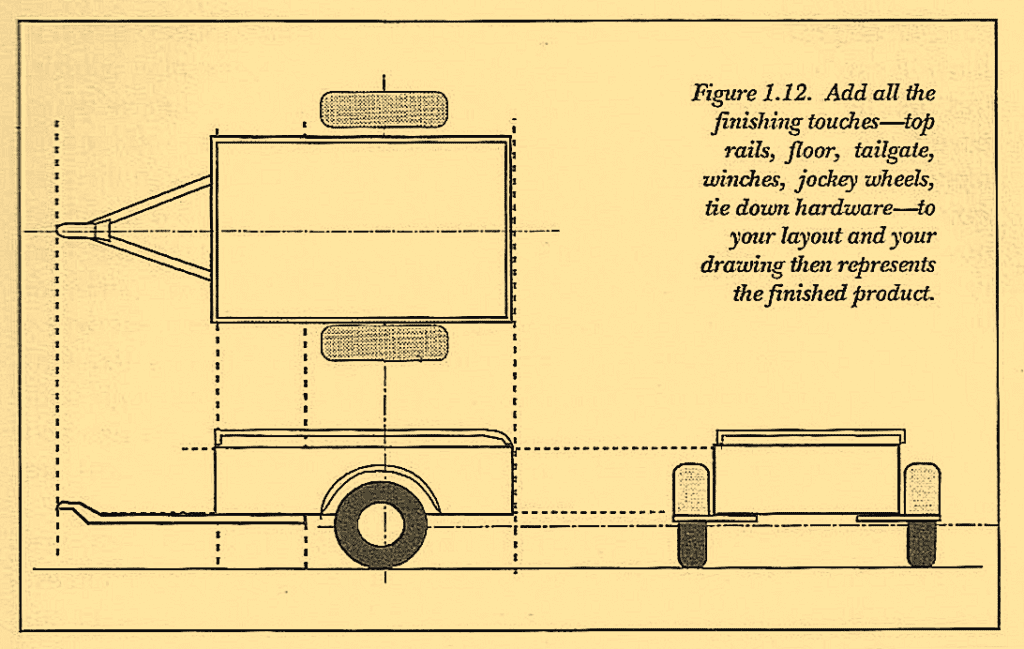

Now you’re ready for the layout drawing: the keeper and recorder of all your work. Actually this is the most exciting part of planning your trailer … especially if you’ve convinced yourself to take your time and do it slowly. This drawing is the ledger of your whole design. All information you concoct or deduce is in some manner eventually recorded on this piece of paper. The six previous steps to organization and success include information that is transferred to this drawing. Laid out to scale, this drawing shows every frame member, suspension part and accessory in its proper and relative position. It has a top view, a side view and probably several end or cross sectional views. The information for this drawing is garnered from calculations, research and shopping and includes cargo dimensions, material sizes, component shapes and dimensions determined from calculations.

Combining this myriad of materials is easily done graphically if each item is drawn to scale, all on separate pieces of paper. The drawings can then be brought together by tracing the separate sketches onto a complete layout drawing. For future changes or additions, the separate drawings provide a good reference. And by drawing each to scale you will also be forced to find the dimensions you are missing.

A standardized lay out of top, front and side views will produce a drawing with the kind of detail needed. The chapters of this book, along with Volume 2 (structural considerations) and Volume 3 (towability considerations), are designed to assist you through the thought processes necessary to produce this drawing. Chapters 3, 4 and 5 of this volume ease the component shopping process, Chapter 2 discusses the overall view of possible creations and their results. Chapter 6 contains suggestions for welding and final assembly of the trailer. TRAILERS—How to Buy & Evaluate also provides an excellent laymen’s summary of Volumes 2 and 3.