Escuber Originals

Fabricated Accessories-Racks & Carriers

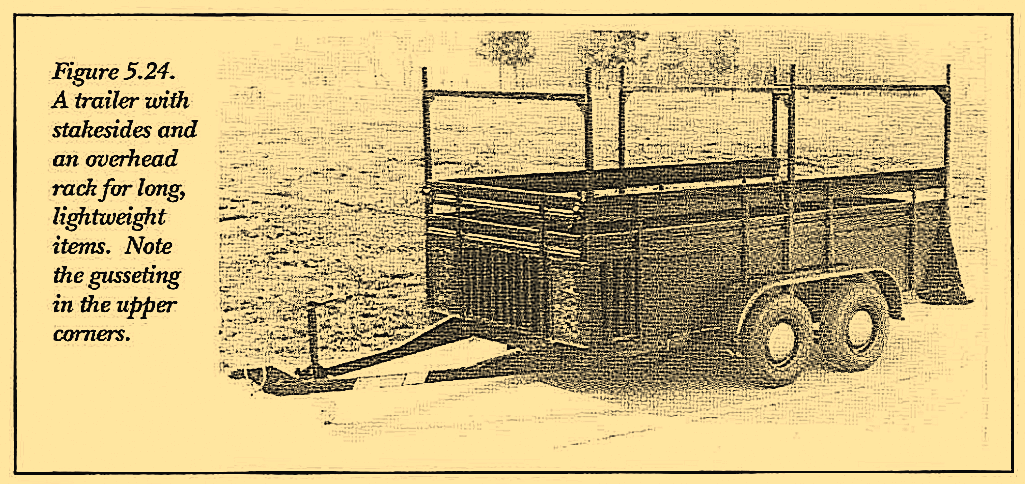

With a trailer, racks and carriers of all types abound. They are smart solutions to cargo that may otherwise be rolling or sliding around. Something you want to keep with the trailer such as gas cans or a spare tire can be conveniently stored with a carrier. If you build a rack up and over anything and you plan to carry any appreciable weight, please be sure it is capable of withstanding the load to be carried. Lightweight items are much easier to carry on an overhead framework than heavier ones. The potential for swaying back and forth is greatly reduced and the load on the joints is not as severe. Whatever the load, calculations similar to the ones presented in Volume 2 will help you determine the material size requirements. Special attention should be given to the design of the joints. An overhead rack is shown on the trailer in Figures 5.24.

A trailer with stakesides and an overhead rack for long, lightweight items. Note the gusseting in the upper corners.

Depending on the purpose of your trailer, accessories specifically for just about any job are available. Horse trailer manufacturers usually offer extra doors, saddle and other tack racks. The trailer can be made longer or taller for large horses or more gear. Boat trailers require few accessories because extra gear can usually be carried in the boat. (But be careful to not overdo it.) Some accessories, such as heavy duty winches and jacks, can become part of the accessory package. Although these additional items increase the basic cost of your trailer, the trade-off in labor and headaches usually makes them well worth the additional investment. Utility trailers can be loaded with accessories for special purposes or be just a bare bones trailer. Equipment trailers need tool boxes and many kinds of special racks, carriers and often a special framework to start with. All this customizing costs money and no matter what its type each trailer is largely a special project. Too many people attempt to compare trailers with items produced in mass-they are not the same thing. Few trailers are produced in large enough mass to qualify as a mass produced item.