Trailers - Design & Build

F. TRAILER BRAKES

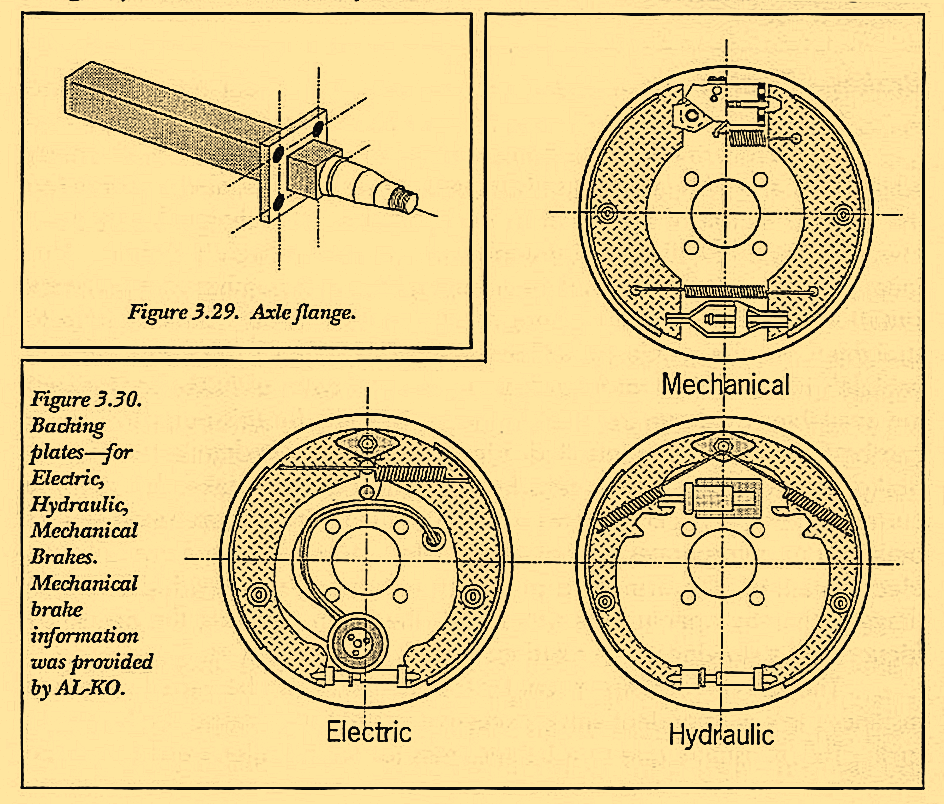

Brakes are an integral part of the suspension system and are used to slow the wheel with friction. When brakes are applied, the shoes are pushed outward against the drum where the friction between the expanded shoes and drum slows the wheel. The backing plates, shown in Figure 3.30, which carry the brake shoes are bolted to a flange, Figure 3.29, which is welded to the axle. The drum, shown in Figure 3.31, is usually cast as an integral part of the hub and provides the surface for the shoes to rub against.

was provided by AL-KO.

Whether or not you will install brakes has to be decided before you purchase hubs, since the drums and hubs are inseparable and must be purchased as a unit. The brakes know to actuate when the appropriate signal initiates from the tow vehicle or nose of the trailer. Actuation at the trailer wheel occurs as a result of this signal which could be hydraulic, electric or mechanical. The apparatus you choose defines the type of system and actuation style.

Many state laws require trailers of certain weights or capacities to have brakes. In California, a trailer weight of more than 3000-lbs gross capacity or 1100-lbs empty requires brakes. It is a good idea to check your own state laws for their limits. Beyond the law, other considerations may influence your decision to install brakes. A smaller tow-car, an extra large motorhome or a tow vehicle of marginal braking capability should influence you to insist on some kind of trailer brakes. Rental trailers of almost all sizes use surge hydraulic brakes to give renters some form of braking. On the other hand, an extra large vehicle (in comparison to the trailer) with little or no cargo and with very good brakes will have a respectable amount of control over its tag-a-long. Unfortunately, for whatever reason, many trailers needing brakes-large as well as small-are without them.