Escuber Originals

F. ELECTRICAL-CONNECTIONS

Electrical connections include not only the individual connectors where two pieces of wire or more are connected but also the main plug at the front of the trailer that is used to connect the electrical system of the trailer to that of the tow vehicle. Since each has its important points, we will discuss each separately.

Electrical–Pigtails

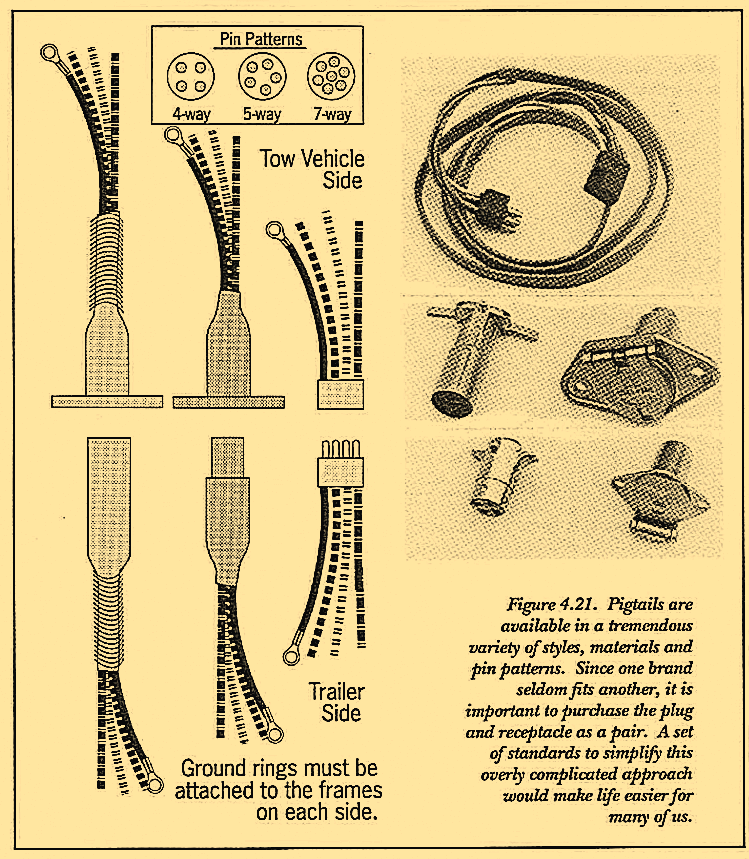

The pigtail and receptacle at the trailer coupling can range from a simple and minimal four wire flat plug that hangs loose, to a seven prong round with bending protection spring. The receptacle is attached to the tow vehicle. It can hang loose or be bolted to the rear of the chassis or bodywork. Right now the quantity and designs of plugs and receptacles is phenomenal, not to mention the price ranges. It’s hard to imagine such a simple product that can take on so many different configurations. but they do. Figure 4.21 illustrates a few of the more common varieties. The plug generally attaches to the trailer. Materials used on these plugs can be metal, plastic or a rubber compound.

My experience is that plugs with metal bodies short out after a period of time due to the rust that develops from being exposed to the elements. In addition assembly is difficult since hooking the wires over the necessarily tiny screws and tightening them can be tedious. This is a job best done with small hands. Alternatively, molded rubber plugs are easy to install and attach to tow vehicle wires: they have been known to resist the elements by not shorting out (on me, anyway) for as long as 10 years.

Because of the current complexities of such a simple product, I would like to suggest that a set of standardized connector dimensions be developed so all plugs, regardless of material, will fit all receptacles, just as they do in your home. With 10 million registered trailers in this country, one has to ask why this has not been done. The heavy duty trucking industry has standardized the plugs used on semi-trailers. Europeans have also standardized their plugs. The telephone industry has standardized its plugs and so has the computer industry. It seems a simple step for our recreational trailer industry to do this. I might suggest a 7-way that can be reduced to a 4 or 5-way with holes that will still fit the basic 7-way receptacle.

Electrical–Connectors

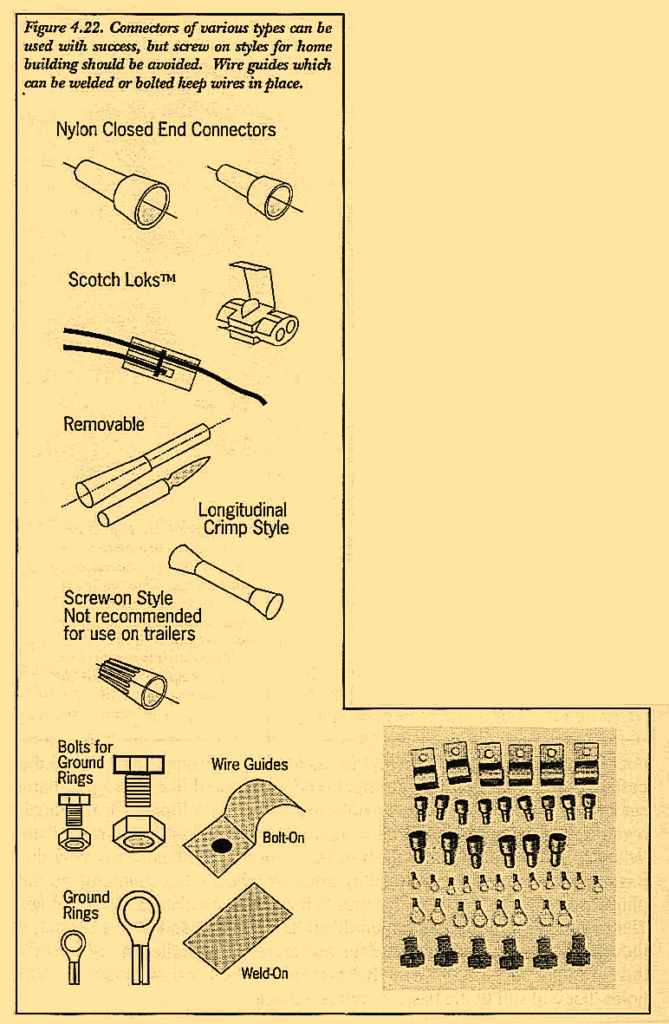

Tying wires together brings another set of special challenges. Connectors are available in many styles; some need special tools, some don’t. The screw on style, requiring no tools, is not appropriate for use on a trailer because these can too easily work themselves loose. These connect- ors are designed for use in homes, which don’t move except in earthquakes. Stripping the wire ends for a clean connection should be done as shown in Chapter 6. If you own a crimping tool, (as pictured in Chapter 6) nylon closed end connectors are probably the easiest and most practical. They cover the exposed ends of the wire and provide a good solid connection. Twisting the wires before crimping, also shown in Chapter 6, will help lock the wires in place. Scotch–loksTM require only a pliers and are an excellent but bulkier choice. Although a bit more expensive, they are also ideal for tapping into continuous wire you don’t want to cut.

Disconnectable styles are available and necessary only for special cases; besides the extra expense, water has been known to leak in, creating a bad connection. Figure 4.22 illustrates some of the connectors from which you have to choose.

To complete the circuit, ground connectors must be part of the system. Ground connections require a little different approach but must not be treated lightly. As you found in the earlier test, Figure 4.13, lights do not work without a good ground connection. The consequence of a loose ground is lights that work intermittently or worse, that work not at all. Most flickering trailer lights can be traced to an inadequate ground. Each light operates because the ground completes the circuit. Thus the connection must be substantial and solid. Rusty mounting surfaces or lead wires bent under the bulb can defeat this requirement. In your tow vehicle the ground cable connects from the battery to a body panel or frame member. Each and every light has one hot wire which connects to a passing wire while the other side touches the frame. The same is true of the trailer-lights are grounded through their mounting bolts; brakes with a wire bolted to the frame. The ground connection between trailer and tow-car is very important and should be accomplished with a wire connection rather than through the ball-coupler attachment as was done in the test and as attempted on many trailers. The small ground ring shown in Figure 4.22, crimped to the wire, and bolted to the trailer frameworks well for this.

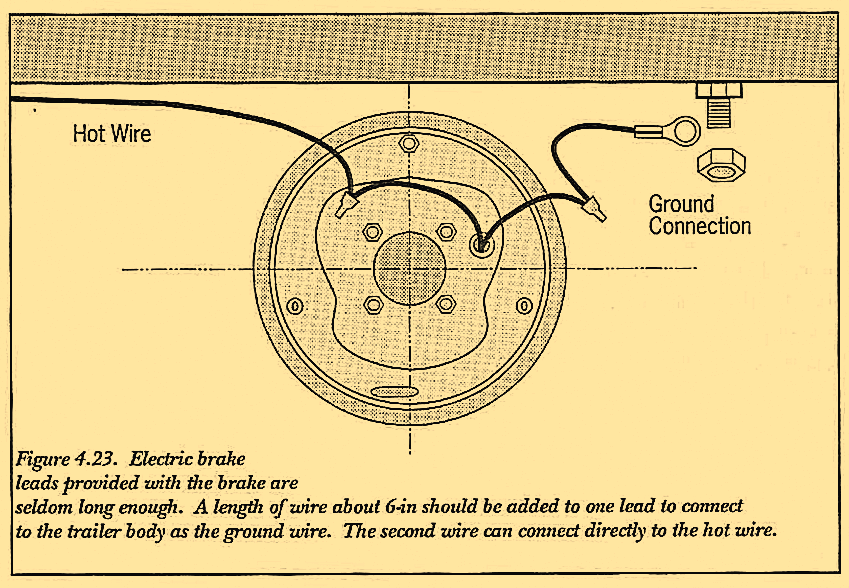

Electric brakes need 2 connections and are provided with 2 protruding wires for this purpose. A ground connector must be used on one of them, while the other is connected to a wire that extends to the front of the trailer and eventually connects to the brake controller in the tow vehicle. A ring or U-shape style connector works well over a bolt that has previously been welded to the framework. In this case a larger ring over a short larger bolt has advantages. My experience is that the pigtail out of standard backing plates never seems to be long enough for trailers I’ve worked on and usually needs to be lengthened by about 3-in to 6-in. Be sure to allow plenty of wire for suspension travel but not so much that it will get tangled. A properly connected trailer wiring system will serve you well. It is worth the effort to design it carefully and install it properly.