Trailers - Design & Build

Brakes-Electric

Electric brakes are a compromise of other systems with many advantages and only a few disadvantages. These brakes never operate off the forward inertia of the trailer as do hydraulic or mechanical. They are always controlled directly by action of the tow vehicle’s driver. This independent control can be of great importance in a number of emergency situations, including sway where a little pull from the rear can help to straighten out the whole rig. Operation of these brakes requires the tow vehicle’s electrical system for actuation. Several types of brake controllers are available which are installed in the tow vehicle for this purpose. These can be foot or handle controlled, triggered by either hydraulic pressure or brake light voltage. All controllers operate electric brakes by sending current to special backing plates which are fitted with electromagnets. The brake drum incorporates an armature plate. When current flows into the electromagnet, the armature plate attracts the magnet, which is then dragged thereby opening the shoes onto the drum, creating the necessary friction and a slowing of the rotation.

The amount of current sent by the controller can be varied. In some instances this is important since excessive current may cause the brakes to lock. This is usually due to a lighter gross (or total) trailer weight than the brake’s design load.

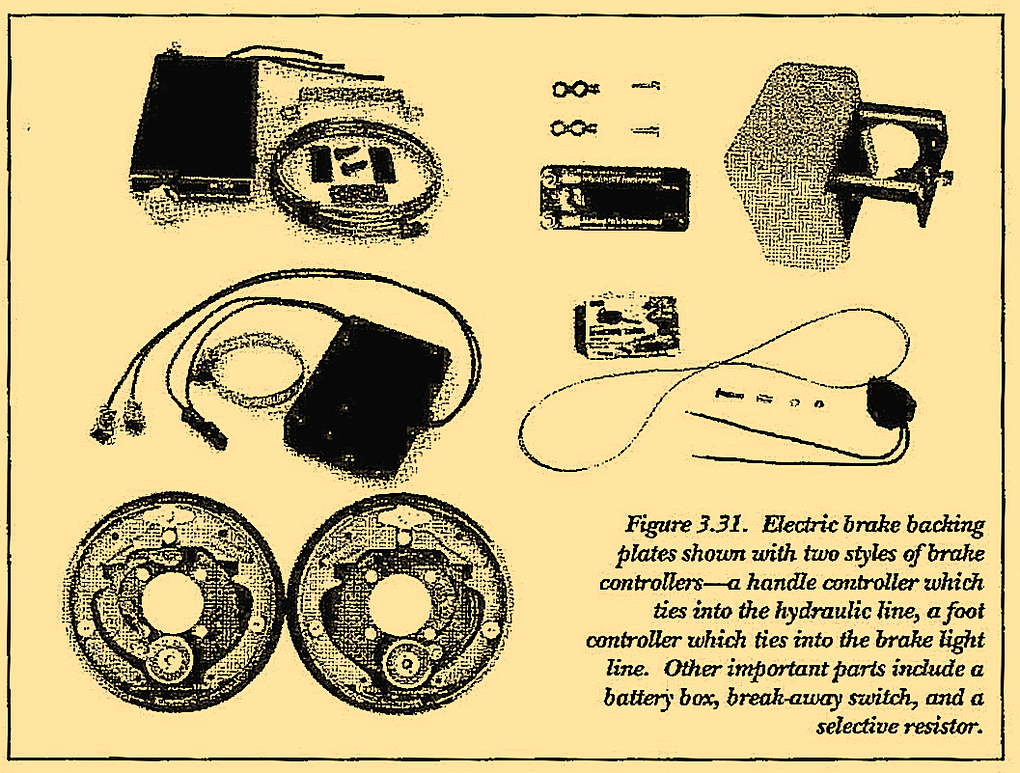

ties into the hydraulic line, a foot controller which ties into the brake light line. Other important parts include a battery box, break-away switch, and a selective resistor.

Adjustments are possible from the controller by twisting the handle. If more adjustment or reduction is needed, a selective resistor shown in Figure 3.31 can be installed. These resistors block and reduce the current flow to the brakes thereby eliminating brake locking due to a trailer weight that is too light.

Figure 3.31 shows several other items required for complete electric brake operation. Besides the basics-backing plates, armature plate and controller-break-away “accessories” are used to operate the brakes in event of a separation from the tow-car. The six-volt battery, its box and break-away switch are installed on the trailer near the coupler. The battery must be checked for juice often, since it will not operate the brakes if the battery is low or dead. The current must be constantly ready to flow through the switch to immediately apply the brakes, if the pin is pulled during a break-away.