Escuber Originals

B. ACCESSORIES

Accessories are an integral part of your trailer and make the trailer do the job initially set out for it. Basic accessories, useful for all trailer’s, include jacks, caster wheels, winches, tie downs and anti-theft devices. Fabricated and special accessories include tailgates, sidewalls, racks, bins and compartments, covers and any other accessories particularly suited to the trailer’s end use. Basic accessories can usually be purchased outright, while many others must be fabricated from scratch. Besides the price of the components the availability of metal working equipment will probably be a factor in your decision to buy, sub-out or make. Jacks and caster wheels, winches, tie downs and some tool boxes can be purchased outright. Products such as these produced on a machine are often far superior to anything you could fabricate. If the styles you want are available, lots of time can also be saved.

Accessories-Trailer Jacks

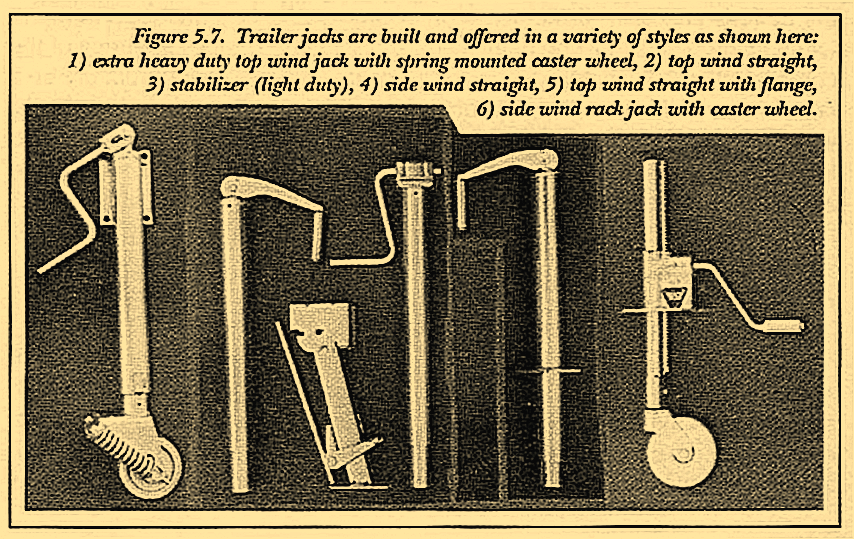

Jacks are available in many styles for a wide variety of different specialized purposes. Jack names-tongue, stabilizer, swivel, side rack lift and extra heavy duty-can refer to placement on the trailer, type of cranking or purpose of use. Jacks can simplify and ease your working with a trailer. Figure 5.7 shows some of the different styles of jacks available.

The most common style of jack is mounted on the trailer tongue with a caster wheel, is called a jockey wheel or tongue jack, and facilitates moving the trailer when it is detached from the tow vehicle. In addition, raising and lowering the coupler into position for connecting and disconnecting to the ball on the tow vehicle is simplified. Using a jack mounted in this position also reduces the potential for back injuries or pinched fingers caused by attempts to lift a heavily loaded trailer tongue onto the tow-car’s hitch ball. I would not own a trailer without one.

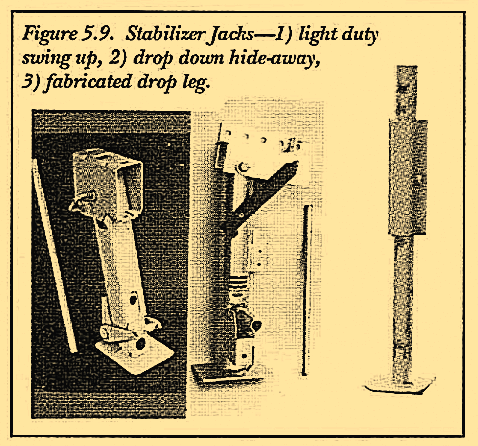

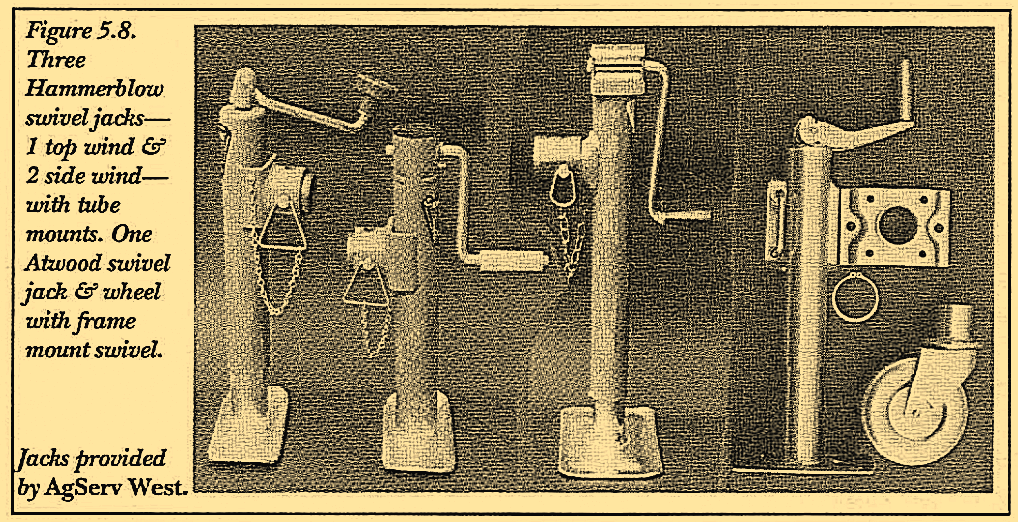

Stabilizer jacks are used when equipment mounted to a trailer bed needs stabilizing while the trailer is stopped and the equipment is in operation. Some of the popular styles are shown in Figure 5.8 and 5.9. Almost any jack with a flat foot attached can act as a stabilizing agent. Many builders have resorted to a square (or round) tube which slides through a larger tube. To modify the height of this drop leg jack, two methods are used-a nut welded to the outer tube with a screw which tightens and holds the position with friction, or several position holes drilled through both tubings which accept a large pin. Swivel jacks, Figure 5.8, have also been a popular choice for this duty because of their strength, convenience and versatility. The swivel mount permits carrying the jack sideways leaving the area above the frame unobstructed for doors to swing open or loads to extend. The available variety of configurations-top wind or side wind, frame or tube swivel mount, a multitude of overall heights and extensions, capacities of 1000-lbs to 5000-lbs, a choice of jack foot or caster wheel-make this style of jack a versatile accessory.

Swing–up, hide-away jacks, Figure 5.9, are also used for stabilizing purposes. These jacks crank up and down like a bumper jack to raise and lower; they then flip up and store horizontally. Be sure to find a secure place to store the handle so it will be readily available when you need it. Lighter duty stabilizer jacks are fine for occasional light loads. I have found these lighter styles, although some are rated at 1000- lbs, unsuitable for anything over a few hundred pounds. Ratings probably come from loadings of pure compression with no side loads; and if that is what you have, the jack is O.K. Unfortunately most applications with trailers include uneven surfaces, resulting in side and offset loads. So take a close look at your situation and know the loads to be resisted. Many of these jacks were originally devised for specific situations and their use has expanded without the upgrading to include provisions for the new duties.