Uncategorized

Accessories-Tie Downs

Tying your load securely to hold it in place while the trailer is moving involves another form of pulling-down and opposite to other tyings. The importance of tie downs for this task cannot be underestimated. I never cease to be amazed at the number of stories I hear about people who fail to tie their loads. Expensive race cars roll off trailers behind motor homes, boats jump forward onto the tow vehicle in a mere emergency stop, unrestrained boxes of metal slide off of flat bed trailers. Pallet dollies roll out of unstaked sides of a flatbed. And there are numerous accidents caused by a change in the trailer’s handling characteristics because of a shift in loading due to inadequate or non-existent tying. Along this line, one of the most bizarre things I have ever seen was a very small fellow riding in the back of a small pick-up truck holding in place an untied extra large and tall refrigerator. The truck was tooling down the freeway at night at 60 mph. I sure hope no emergency swerves were necessary because there is no way that giant refrigerator could have been held in place by that little person.

My guess is that most people have little idea how much force increases with velocity and what acceleration does to increase the effective weight of an item. In the early 70’s, race cars generated as much as 1.7-g’s in high speed cornering. Because of technological advancements, these cars now generate as much as 3-g’s. G-loads of as little as .3-g’s can be felt as a slight side tug in a slow corner. It makes cornering feel to a rider just a little uncomfortable…or exciting, whatever your emphasis. What does G- load mean?

Downward weight from gravity would be referred to as 1-g. For instance, if an item weighs 100-lbs, its downward force is 100-lbs. And, if a corner is a 1-g corner, the sideways force will be 100-lbs. Imagine trying to hold something that weighs as much sideways as from underneath. In a 0.3-g corner, the sideways force of a 100-lb weight will be 30-lb. So all of a sudden, this thing standing by itself has what appears to be sideways weight. Seat belts and tie downs are a welcome restraint to those who understand these forces.

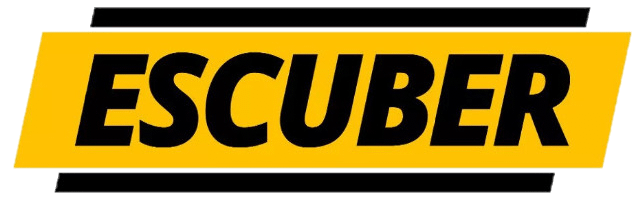

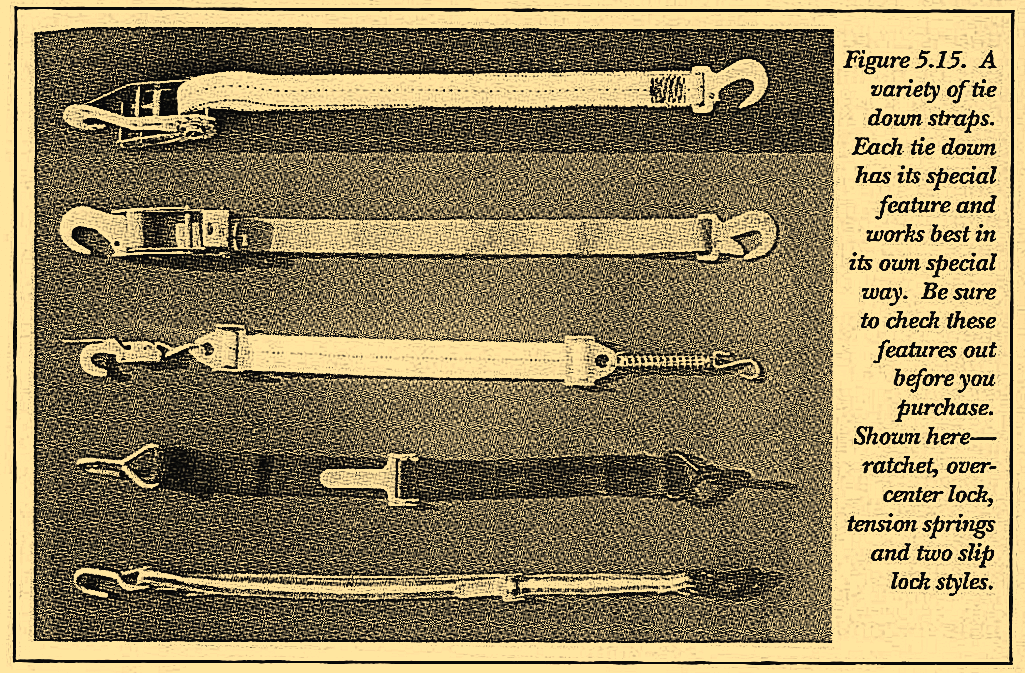

Tie downs shown in Figure 5.15 are only a sampling of those currently available from various manufacturers. Ratchet-to-tighten, over- center locks, slip locks and tension springs-each has its own specialty. The type of load you are hauling will have a lot to do with the one most appropriate for your application. Rope can also be used but it needs to be heavy duty nylon or sisal rope. Knotting and looping the rope properly so it won’t work loose are also important. Do check the rating of the rope, and obtain the strongest one your budget will allow and your load needs. Small load binders shown in Figure 5.16 are another way to hold a load in place. They can be employed with chain or strap or hooked directly to the load. These tie downs take after their big brothers used to bind chain tightly over heavy loads such as steel on big trucks and are often called chain binders. For palletized loads and automobiles with existing cargo tie down loops these devices are quite handy. From 250-lbs to 1200-lbs capacity, these little jewels will handle a variety of loads.

Tying your load should be planned during trailer construction since welding may be required to install pick-up points and use the tie downs properly.

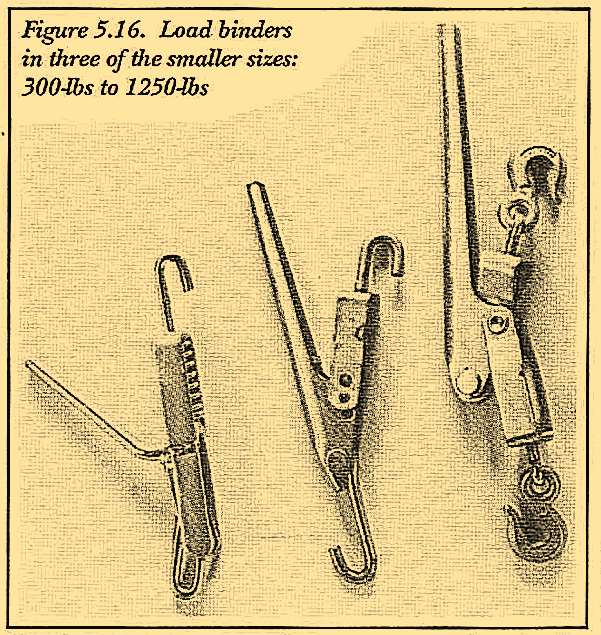

Tie down loops come in many styles some of which are shown in Figure 5.17. Here we have both weld-on and bolt-on styles. A popular style pulls up through the floor or through the wall and lays flat when the tie down is disconnected. On areas where tires roll or people walk, I have found square bend U-bolts to be a success- ful solution. Many cargoes need accurate placement of the loops to ensure the proper angle of tying. An advantage to these loops. is that they can be positioned after the trailer is complete and painted. If done while the cargo is in place, the most appropriate placement will result. Note that square bend U-bolts have double the thread and nut area that a single bolt would have. With a large bearing plate under the nuts, a good capacity can generally be achieved.

An eyebolt and a nut ringbolt are also shown in Figure 5.17. Hardware store varieties have capacities equivalent to their grade of bolt which is generally at the lower end. I do not recommend this quality for use on a trailer. On the other hand, industrial quality items have much higher capacities (higher prices, too) and may be worth looking into. Note that these loops secure their loads with one thread and nut. Extra large and thick washers or plates should be used to spread pull through loads applied to the parent material. Volume 2 discusses calculations to determine if the tie down hardware and its attachment is adequate for your application.

Attachment of eyebolts and nut ringbolts to a trailer’s generally lighter material is sometimes difficult. An improvement is available with the Ty–d-eyetm, whose patented design allows easy adaptation to a variety of trailer frames and cargoes. The longitudinal welds placed in two perpendicular directions provide substantial attachment strength. Welding surfaces can also be virtually in the same plane as the loop itself. A bolt-on style where the bolts are in shear in one or two perpendicular planes makes installation easier for completed trailers. Loads tied diagonally (Arrow A, Figure 5.17) gain maximum strength; loads tied perpendicular (Arrow B) tax this tie down to its maximum. Whatever your choice, an adequate quantity of tie downs using substantial attachment methods are essential.

STEEL EYEBOLTS & NUT RINGBOLTS

Since this method depends on only one nut and one thread, knowing the capacity of each is a must. Capacities stated are for tension only; an angled load decreases capacity significantly. Large thick washers are highly advised.

SQUARE BEND U-BOLT

Recommended for sides and floors, where people walk or wheels roll. Two nuts and washer plate distribute load over large area.

TY-D-EYEtm

These versatile tie down loops provide extra weld area for attachment to lighter trailer structures. Capacity is greatest in direction of Arrow A. Arrow B direction provides minimum strength. Contact Techni-Visions for more information regarding usage, strength and availability.

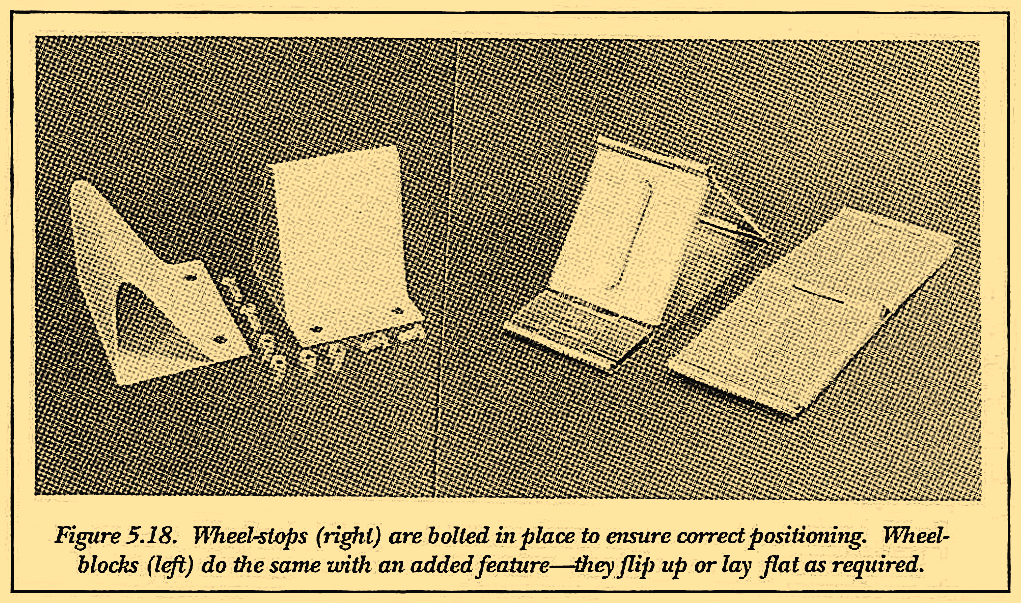

If your cargo is an automobile, remember that vehicle tires are designed to roll. Unfortunately that is the last thing you want if the vehicle is atop a trailer. Contrary to some thinkers, leaving the car “with brakes on and in gear” alone will not keep that vehicle in place. Methods to prevent rolling, though, can be a real challenge. Besides the basic tie downs, which are a must, there are a few other helpful products. Figure 5.18 shows two such items a wheel-stop and a wheel-block. Wheel-stops act as a sure stop at the exact forward position you want the vehicle to rest. Obtaining the optimum tongue weight, trailer balance and weight distribution is much easier with a pair of these stops. Bolting them in place rather than welding retains the flexibility should you change vehicles. Wheel-blocks also work great in the same duty but are more appropriately used to prevent rolling in the opposite direction-such as at the rear of the car. They lay flat as the car rolls over them while being loaded; then pop-up behind the car to hold it in place. Both of these products are great to use as stops, but act only as forward and backward restrictors. Tie downs are always required in addition for complete security.