Escuber Originals

Accessories-Caster Wheels & Jack Mountings

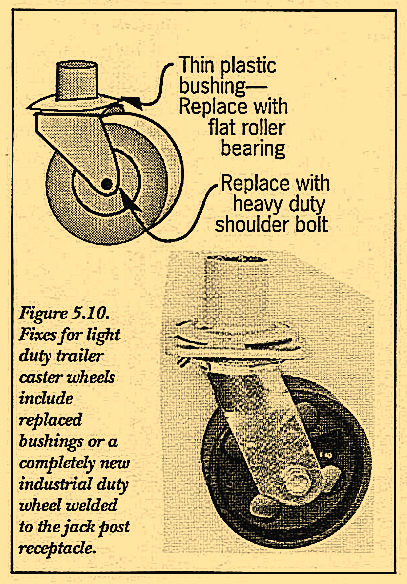

Caster wheels are currently a subject of great concern to many-as they are quite popular but somewhat marginal in nature. A more durable wheel to replace those currently available would certainly be a welcome product. Caster wheels for jacks were largely designed for use on tongue jacks. The marginal caster wheels are rated at 1000-lbs. Where this rating comes from, I don’t know. My experience finds those currently in existence to be fine as long as the trailer sits unloaded on the showroom floor and for a short time thereafter. If the trailer is loaded (which is the reason one wants the jack in the first place) with, say, a 300-lb tongue weight and is then pushed over anything except smooth concrete, the plastic bushing at the center of the wheel pops out and, of course, the wheel must be replaced. In addition, the thin plastic bushing used at the top to assist swivelling not only embrittles, but easily acquires dirt particles, squashes and breaks apart, rendering the swivel mechanism totally ineffective.

Many people I talk to are rather unhappy with this flimsy product and refuse to buy a new one-can you blame them? The few who do, discover the process merely repeats itself. My solution for reworking this wheel is to first cut the riveted axle off (not an easy task) and replace it with a heavy duty shoulder bolt of the proper diameter. A flat roller bearing (preferably sealed) can then be installed for the top swivelling. An easier way (slightly more expensive though) is to completely discard the existing wheel and save the top (for sliding onto the jack). Purchase an industrial quality steel caster with ball bearings and with a flat mounting plate (for bolting or welding into place). Weld this flat mounting plate of the caster wheel assembly to the bottom of the trailer caster wheel top and a durable heavy duty wheel results, as pictured in Figure 5.10.

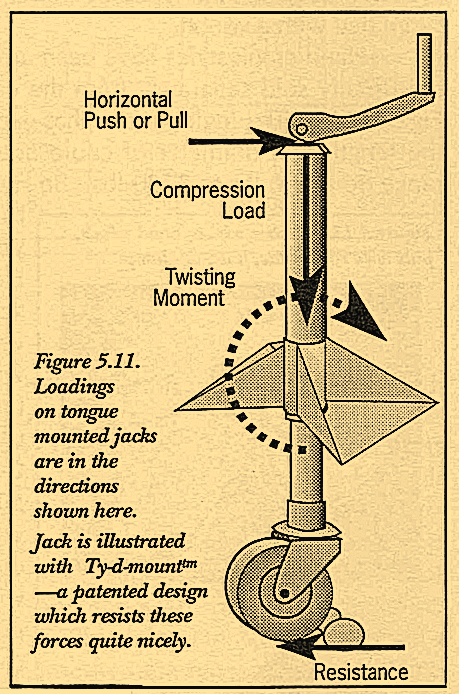

Overall capacity ratings for jacks are apparently difficult to derive. Most are rated at 1000-lbs or 5000-lbs. What does that mean? It appears to mean that this sort of load can be withstood in a vertical direction. For some situations, especially where a jack foot is used, this is what is needed. If, however, the jack is used as a tongue jack with a caster wheel, other twisting loads. also come into play, as shown in Figure 5.11.

with Ty-d-mountm -a patented design which resists these forces quite nicely.

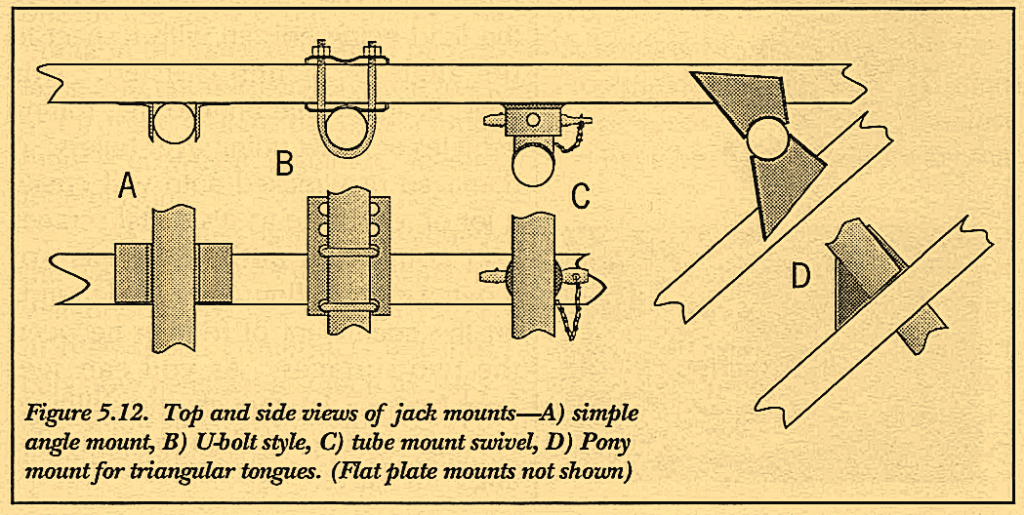

The sideways move- ments, and dimensions from ground to mount, result in an extra beating for jack mounts. Currently common ways of mounting a jack include angle mounts, U-bolt mounts, frame and tube swivel mounts, flat plates and the Pony jack mount-as shown in Figure 5.12.

Simple angle mounts have been used successfully on small lightweight trailers but my experience finds them to be marginal when side loads from a big trailer with a heavy tongue weight are applied. U-bolt mounts depend on friction to hold the vertical position, have that “add-on” look and can leave “shin- catching” sharp protrusions unless the U-bolts are pointed inside (jack has to be mounted outside and off center). The patented Pony jack mount used by IRD for several years was designed to overcome several of these problems and has proven to be effective. Contact Techni- Visions for current availability of these extra strong jack mounts.

Swivel jacks require a different approach. These mount- ings are offset to the jack’s side. For jacks fitted with a foot, side loads are minimal. With a caster wheel though, they face some of the same problems as an angle mount. Heavier, larger mountings are definitely recommended, and are in most cases provided. In spite of a few drawbacks, properly and well thought out mounted jacks, used as designed, can be well worth their expense in assisting you to move or stabilize your trailer.