Trailers - Design & Build

A. SAFETY DEVICES

Let’s start with safety devices since all trailers are required to have some of these. These parts occupy a minority of spaces in the list of trailer accessories. They include safety chains, coupler lock pins, break-away locking mechanisms for electric and surge brakes and tie downs. The break-away switch for electric brakes, which is activated should the trailer become separated from its tow vehicle, was discussed in Chapter 3 in the section on brakes. Surge and mechanical brakes are also equipped with a break-away locking device in the form of a lever and a chain that hooks loosely to the tow vehicle. If the trailer breaks away, the chain is pulled activating the brake mechan- ism thereby applying the brakes. Tie down straps, along with stakesides and tailgates may also be con- sidered a form of safety device since they act to hold everything in place which would otherwise not be held. We will discuss these shortly.

Safety chains are required on all trailers; even so, they usually elicit a bit of controversy. Many owners say they’d rather the chain break and the trailer run loose if the trailer and tow vehicle separate. Others know the dire consequences of that scenario and the importance of the trailer staying with something steerable. Of course, if your tow vehicle is not sufficient in size to be towing the trailer in the first place, any mishap can be disastrous.

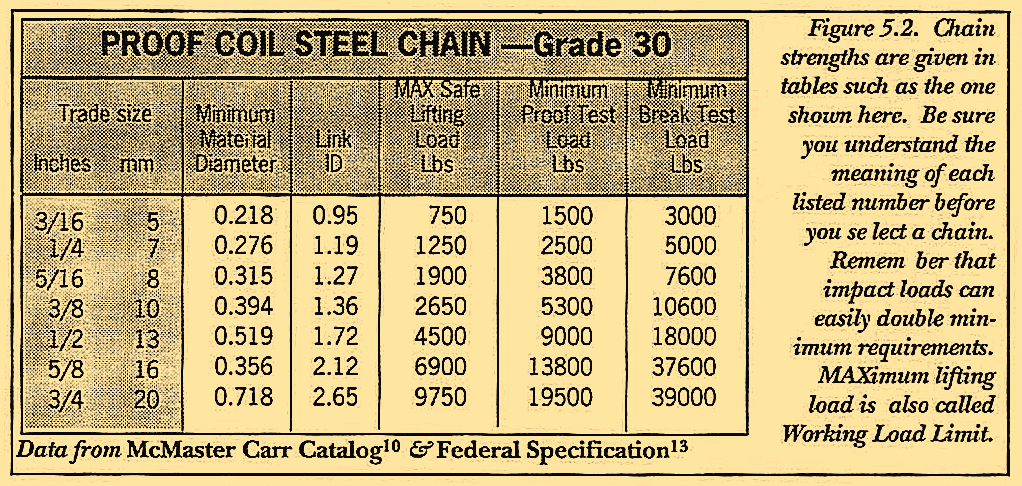

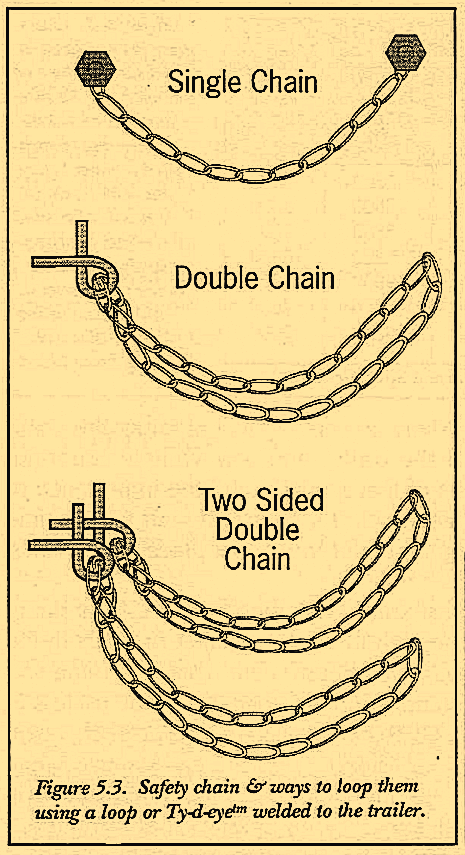

Whatever your opinion, most state laws require the use of safety chains. Chains need to be heavy enough to hold the trailer in place in the event of break-away. You may never need to use them, (and let’s hope you don’t), but if the chains won’t withstand an impact load, they’ll be useless in that once-in-a-lifetime event. Figure 5.1 shows a few examples of chains in common use. Strengths of chain are listed in Figure 5.2. A single chain can be figured to have the strength listed in the chart. Two chains or a loop of chain effectively doubles the load capability. A double set of chain loops quadruples it. Figure 5.3 illustrates these configurations. If the chain is used for lifting and moving, it will be subjected to “working loads.” For this use, the working load limit given in most chain specification tables is vital to observe. With a trailer, though, the chain typically hangs loose waiting for that one emergency impact load. Here the load of interest is the breaking strength (Figure 5.2). However, using the proof test load provides a better margin of safety. The best advice is to be conservative and by all means query your supplier for the exact load rating.

The weakest link in a chain connection is often its attachment to the trailer, especially if the chain end is welded. Chains are not designed to be welded. As with springs, the careful preparation of alloys and heat treating is too easily undone by a weld. A U-loop or eye loop of heavier hot rolled or cold rolled bar 1/4-in to 3/8-in will not only give a good length of weld-3-inch to 6-inch-but also strength to match that of the chain. The damage to the chain links instilled by the welding process is thus avoided.

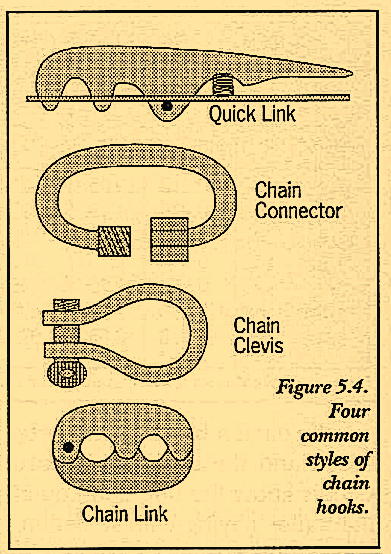

Connecting the loose ends of chain together is another puzzle. Too often the solution is the most easily grabbed bolt and nut that will fit through the links-an unsatisfactory choice due to the potential lack of strength and inconvenience of use. Inexpensive devices shown in Figure 5.4 are generally referred to as chain hooks. These devices make it much. easier and more reliable to connect the chain ends. Most are available in a variety of strengths. Just be sure to coordinate the strength of this part with that of your chain.

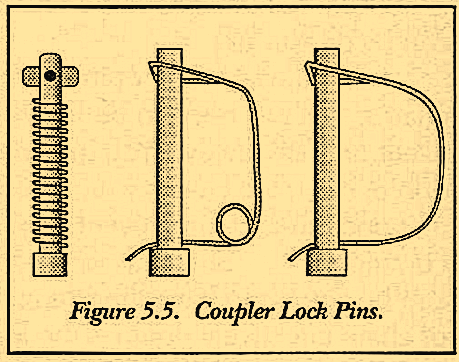

The coupler lock pin is another piece of hardware for safety, as well as convenience. It is designed to prevent accidental opening of the coupler latch. Too often, a nut and bolt is used-again, a less than desirable solution due mostly to the inherent weakness of the threaded shaft. A few lock pin styles are shown in Figure 5.5. Finding a pin like this with the correct diameter usually requires some searching, since few trailer com- panies carry them. A search of one or two specialty, well-equipped, hardware stores may be a better source and yield a find more quickly.